Pompa pasir pipa

introduksi produk:

ZNG seri pipeline nyandhang-tahan pump lumpur dirancang adhedhasar prinsip pump pipo.Bagean aliran digawe saka bahan paduan tahan nganggo kekuatan dhuwur, sing nduweni resistensi nyandhang sing apik.Watesan aliran gedhe.Pasir, slurry mineral, slurry batu bara, pasir lan media partikel padhet liyane.Bisa ngganti pompa lumpur horisontal tradisional, digunakake ing tanduran perawatan limbah, ekstraksi slag tanduran tenaga termal, slag wesi tanduran baja, perusahaan industri lan pertambangan, lsp.

Model tegese:

ZNG-pipeline mud pump

ZNGX-stainless pipeline pompa lumpur

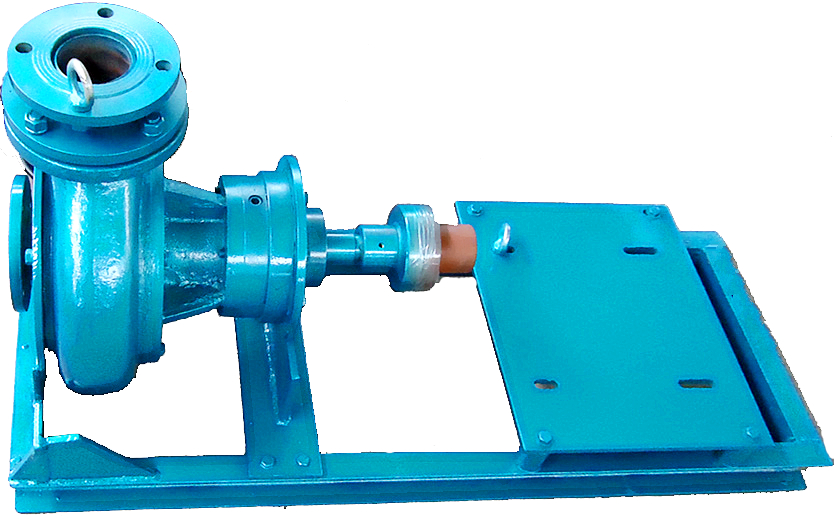

WZNG-Pompa sedimen pipa horisontal

WZNGX-Pompa sedimen pipa horizontal baja tahan karat

Awak pump nggunakake desain saluran aliran gedhe, kang nduweni granularity gedhe lan passability apik.

Impeller, awak pompa lan bagean aliran liyane digawe saka bahan paduan tahan nyandhang, sing tahan nyandhang.

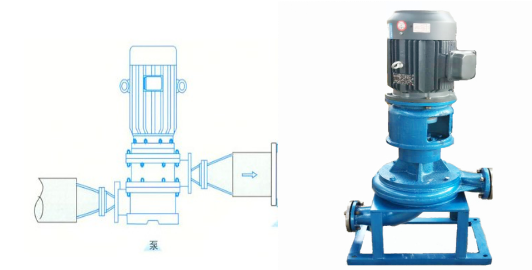

Nganggo struktur vertikal, ngirit papan, instalasi gampang lan efisiensi dhuwur kabeh mesin.

Pompa kasebut duwe ruang lenga lan segel mekanik alloy hard.

Cara instalasi motor pompa pipa ZNG vertikal, arah aliran padha karo arah panah ing awak pompa.Iki nganggo prinsip low in lan high out.

Panggunaan produk:

1. Nindakake pressurization sekunder ing pipa saka pump endhepan submersible kanggo éling transportasi long-distance saka endhepan.

2. Tinimbang Pumps horisontal tradisional, tambang batu bara, pembangkit listrik, tanduran perawatan limbah lan Enterprises transportasi slurry ngemot partikel ngalangi, etc., lan konsentrasi medium transportasi bisa tekan liwat 40%.

3. Iku cocok kanggo ngangkut slurry tailings, slurry wedhi, slag, lendhut, mortir, quicksand lan endhot seluler saka saluran limbah kutha, uga cairan lan cairan korosif sing ngemot residu silt.

4. Medium pangirim kayata wedhi, slurry bijih, slurry batu bara, pasir lan kerikil sing ngemot partikel padhet gedhe.

Wigati sadurunge nggunakake:

1. Sadurunge miwiti, kasebut kanthi teliti, mriksa apa pump pipo wis deformed utawa rusak sak transportasi, panyimpenan lan instalasi, lan apa fasteners ngeculke utawa Mudhun.

2. Kebocoran, mundhut fase, piranti proteksi arus kakehan lan kakehan kudu diinstal sadurunge digunakake

3. Priksa manawa unit sumber daya aman lan dipercaya, lan voltase sing dirating kudu cocog karo nameplate.

4. Segel flanges inlet lan outlet lan flanges pipa saka pompa karo gaskets karet lan sambungake kanthi kuat.

5. Ngalih poros pump sawise motor diinstal, ora ana jamming utawa akeh gesekan, yen motor kudu diinstal maneh langsung.Bobot pipa ngirim ora ditambahake menyang pompa nalika instalasi supaya ora deforming pompa.

Ndandani lan pangopènan pompa pipa

1. Ajeg mriksa resistance jampel tissue antarane pump nduwurke tumpukan lan casing.Resistance insulasi kudu luwih saka 20MΩ.Yen ora, langkah-langkah sing cocog kudu ditindakake kanggo nyukupi syarat sadurunge digunakake.

2. Ing kahanan kerja normal, sawise pompa listrik bisa digunakake sajrone 3-6 sasi, pangopènan kudu ditindakake, ngganti bagian sing rusak lan nyandhang, mriksa status pengetatan, ngisi utawa ngganti pelumas bantalan lan lenga mekanik ing kamar minyak.Priksa manawa pompa listrik bisa digunakake kanthi apik.

3. Pompa booster pipa ora digunakake kanggo wektu sing suwe.Pipa kasebut kudu dibongkar lan banyu sing akumulasi ing pompa kudu dikeringake.Bagian utama kudu di resiki, tahan karat lan garing, diselehake ing papan sing garing lan berventilasi, lan disimpen kanthi bener.

Data model ZNG, ZNGX, WZNG, WZNGX

| Ora. | Model | Ftingkat kurang M3/jam | Head m | Ddiameter mm | Power kw | Granularity mm |

| 50ZNG15-25-3 | 15 | 25 | 50 | 3 | 10 | |

| 50ZNG30-15-3 | 30 | 15 | 50 | 15 | ||

| 50ZNG40-13-3 | 40 | 13 | 50 | 15 | ||

| 50ZNG50-10-3 | 50 | 10 | 50 | 20 | ||

| 50ZNG24-20-4 | 24 | 20 | 50 | 4 | 20 | |

| 50ZNG40-15-4 | 40 | 15 | 50 | 20 | ||

| 80ZNG60-13-4 | 60 | 13 | 80 | 20 | ||

| 50ZNG25-30-5.5 | 25 | 30 | 50 | 5.5 | 18 | |

| 80ZNG30-22-5.5 | 30 | 22 | 80 | 20 | ||

| 100ZNG65-15-5.5 | 65 | 15 | 100 | 25 | ||

| 100ZNG70-12-5.5 | 70 | 12 | 100 | 25 | ||

| 80ZNG30-30-7.5 | 30 | 30 | 80 | 7.5 | 25 | |

| 80ZNG50-22-7.5 | 50 | 22 | 80 | 25 | ||

| 100ZNG80-12-7.5 | 80 | 12 | 100 | 30 | ||

| 100ZNG100-10-7.5 | 100 | 10 | 100 | 30 | ||

| 80ZNG50-26-11 | 50 | 26 | 80 | 11 | 26 | |

| 100ZNG80-22-11 | 80 | 22 | 100 | 30 | ||

| 100ZNG130-15-11 | 130 | 15 | 100 | 35 | ||

| 100ZNG50-40-15 | 50 | 40 | 100 | 15 | 30 | |

| 100ZNG60-35-15 | 60 | 35 | 100 | 30 | ||

| 100ZNG100-28-15 | 100 | 28 | 100 | 35 | ||

| 100ZNG130-20-15 | 130 | 20 | 100 | 37 | ||

| 150ZNG150-15-15 | 150 | 15 | 150 | 40 | ||

| 150ZNG200-10-15 | 200 | 10 | 150 | 40 | ||

| 100ZNG70-40-18.5 | 70 | 40 | 100 | 18.5 | 35 | |

| 150ZNG180-15-18.5 | 180 | 15 | 150 | 40 | ||

| 100ZNG60-50-22 | 60 | 50 | 100 | 22 | 28 | |

| 100ZNG100-40-22 | 100 | 40 | 100 | 30 | ||

| 150ZNG130-30-22 | 130 | 30 | 150 | 32 | ||

| 150ZNG150-22-22 | 150 | 22 | 150 | 40 | ||

| 150ZNG200-15-22 | 200 | 15 | 150 | 40 | ||

| 200ZNG240-10-22 | 240 | 10 | 200 | 42 | ||

| 100ZNG80-46-30 | 80 | 46 | 100 | 30 | 30 | |

| 100ZNG120-38-30 | 120 | 38 | 100 | 35 | ||

| 100ZNG130-35-30 | 130 | 35 | 100 | 37 | ||

| 150ZNG240-20-30 | 240 | 20 | 150 | 40 | ||

| 200ZNG300-15-30 | 300 | 15 | 200 | 50 | ||

| 100ZNG100-50-37 | 100 | 50 | 100 | 37 | 30 | |

| 150ZNG150-40-37 | 150 | 40 | 150 | 40 | ||

| 200ZNG300-20-37 | 300 | 20 | 200 | 50 | ||

| 200ZNG400-15-37 | 400 | 15 | 200 | 50 | ||

| 150ZNG150-45-45 | 150 | 45 | 150 | 45 | 40 | |

| 150ZNG200-30-45 | 200 | 30 | 150 | 42 | ||

| 200ZNG350-20-45 | 350 | 20 | 200 | 50 | ||

| 200ZNG500-15-45 | 500 | 15 | 200 | 50 | ||

| 150ZNG150-50-55 | 150 | 50 | 150 | 55 | 40 | |

| 150ZNG250-35-55 | 250 | 35 | 150 | 42 | ||

| 200ZNG300-24-55 | 300 | 24 | 200 | 50 | ||

| 250ZNG600-15-55 | 600 | 15 | 250 | 50 | ||

| 100ZNG140-60-75 | 140 | 60 | 100 | 75 | 40 | |

| 150ZNG200-50-75 | 200 | 50 | 150 | 45 | ||

| 150ZNG240-45-75 | 240 | 45 | 150 | 45 | ||

| 200ZNG350-35-75 | 350 | 35 | 200 | 50 | ||

| 200ZNG400-25-75 | 400 | 25 | 200 | 50 | ||

| 200ZNG500-20-75 | 500 | 20 | 200 | 50 | ||

| 150ZNG250-50-90 | 250 | 50 | 150 | 90 | 44 | |

| 200ZNG400-40-90 | 400 | 40 | 200 | 50 | ||

| 250ZNG550-25-90 | 550 | 25 | 200 | 50 | ||

| 200ZNG400-50-110 | 400 | 50 | 200 | 110 | 50 | |

| 300ZNG660-30-110 | 660 | 30 | 200 | 50 | ||

| 300ZNG800-22-110 | 800 | 22 | 300 | 50 | ||

| 300ZNG500-45-132 | 500 | 45 | 200 | 132 | 50 | |

| 300ZNG700-35-132 | 700 | 35 | 200 | 50 | ||

| 300ZNG1000-22-132 | 1000 | 22 | 300 | 50 |